algae-based leather

Plant-based and sustainable alternative to animal leather aiming for the quality of traditional animal leather.

why algae?

Algae are considered the fastest growing microorganisms as they are highly efficient in photosynthesis, wrote Thought.co. As a result, algae are abundant in nature and are capable of producing oxygen through the process of photosynthesis. Further, discussion with Atelier LUMA resulted to a conclusion that making alternative leather from algae for shoe creation is a strong idea as algae have remarkable properties and positive health effects. Important note to highlight though is to concentrate on elaborating the material binder and further explore the possibilities of making this material flexible.

research process

seaweed species

selected to be researched

experimented in this research

The objective of this research is to find the best way to process algae into leather alternative material and eventually use the mentioned material into a sneaker.

The following steps were taken to fulfil the above research objective:

A. Creation of a durable algae-based leather

- Collecting seaweed

- Selecting and exploring seaweed species and their positive effects on body

- Processing seaweed from the sea

- Developing binding agents

- Making of plant-based material

B. Creation of a sneaker using the algae-based leather

- Sneaker pattern

- Creating outsole

- Assembling sneaker

- Final result

a. creation of a durable algae-based leather

1. collecting seaweed

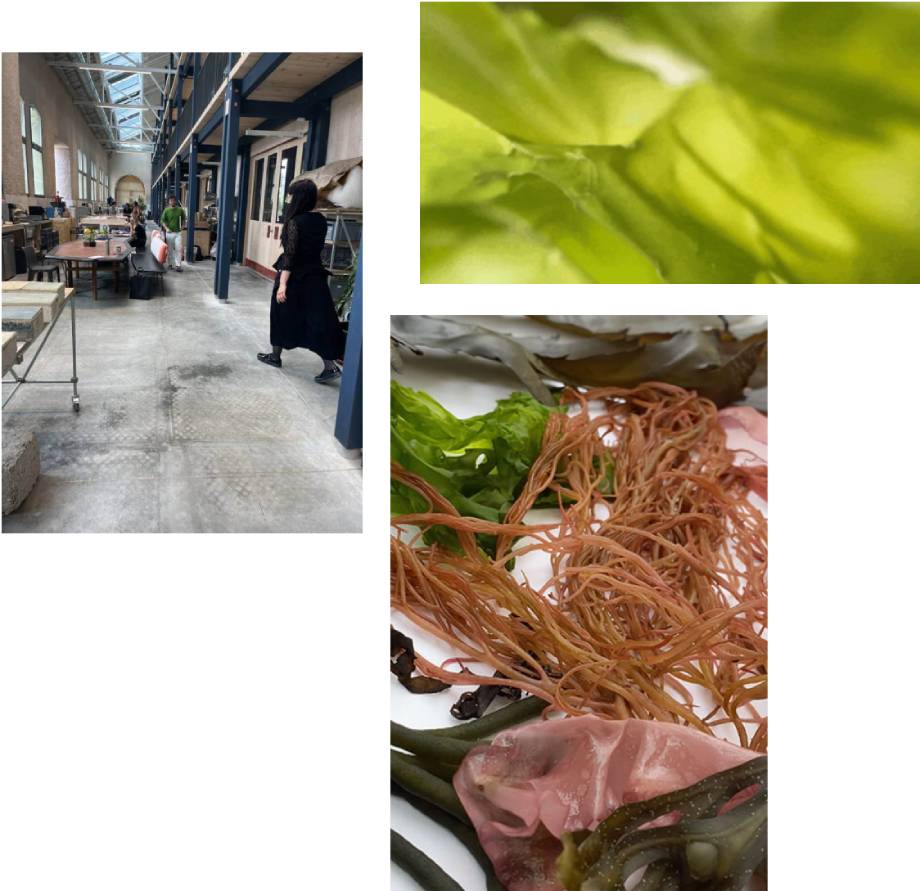

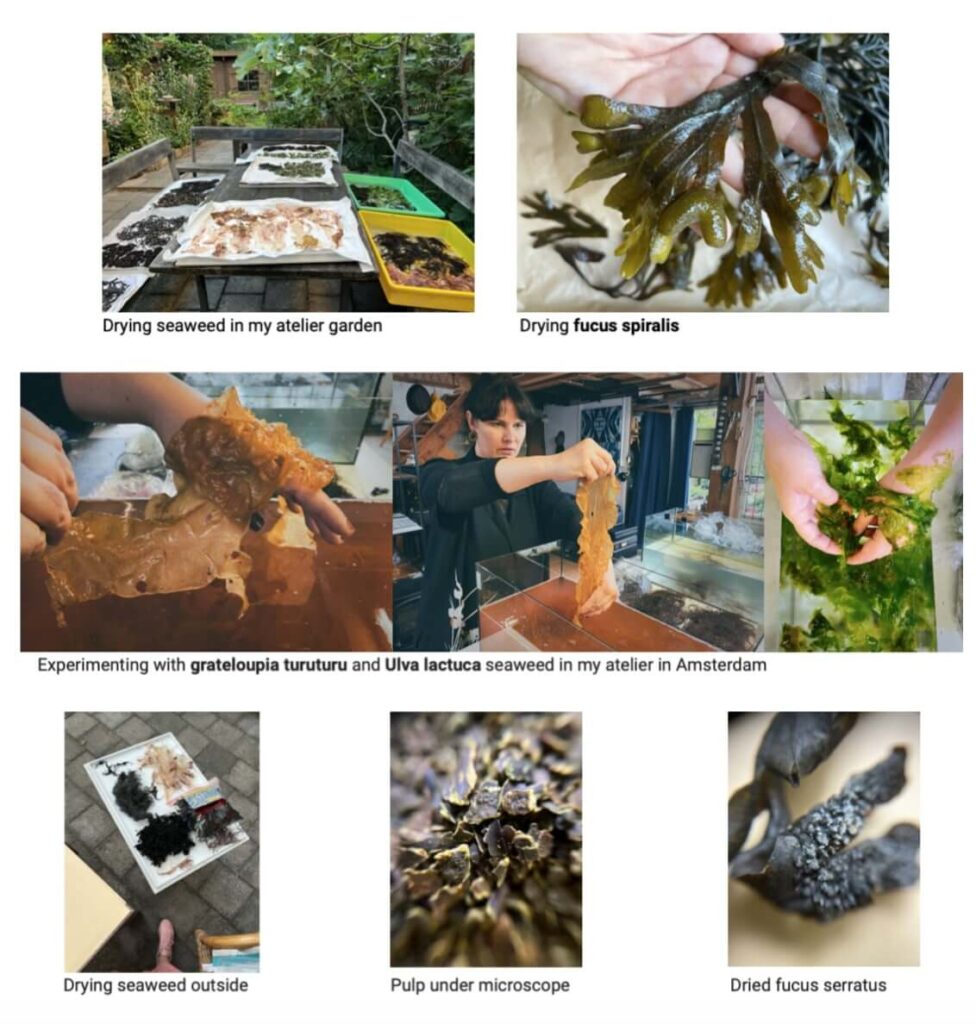

For this research, I visited dikes along the North Sea coast of The Netherlands and collected variation of seaweed types.

2. selecting and exploring

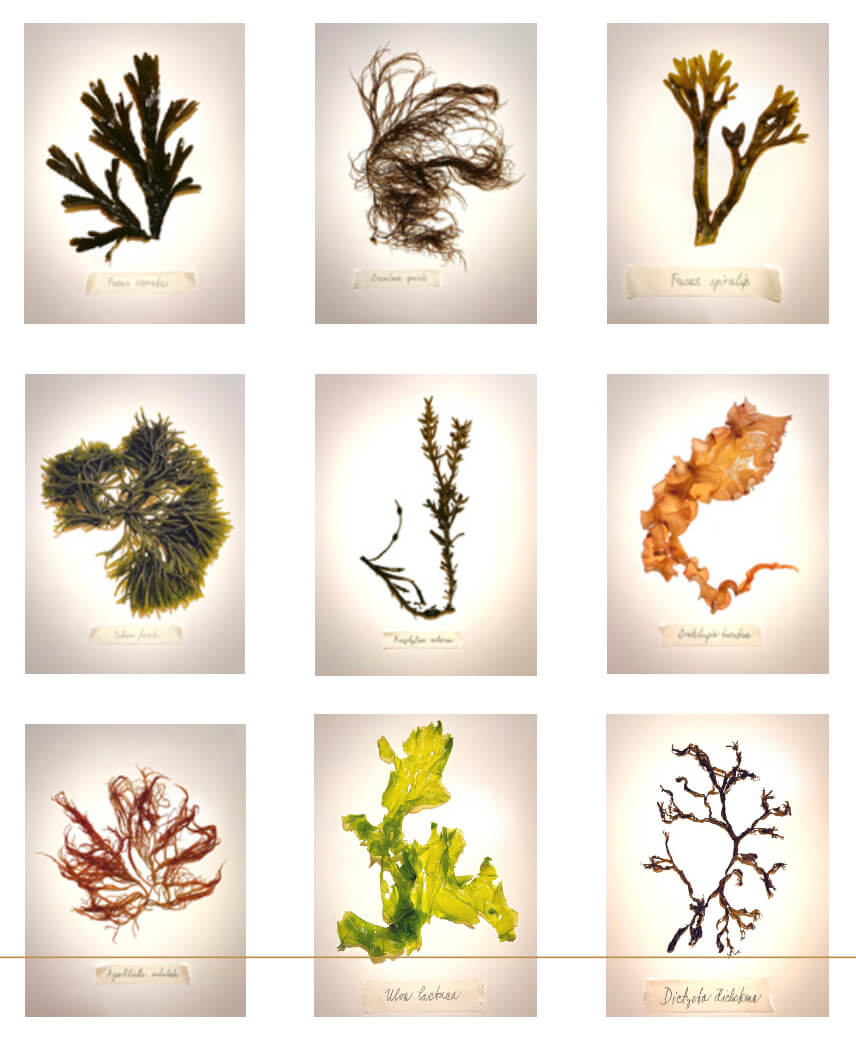

There are 275 species of seaweed in The Netherlands, of which I was able to collect 9 different species from the dikes along the North Sea of The Netherlands: fucus serratus, fucus spiralis, ascophyllum nodosum, codium fragile, agardhiella subulata, ulva lactuca, grateloupia turutura, dictyota dichotoma en gracilaria gracilis, my experiment focused on seaweed which might have positive effects on the human body:

- Fucus serratus | brown seaweed

- Ascophyllum nodosum | brown seaweed

- Grateloupia turuturu | red seaweed

- Ulva lactuca | green seaweed

3. processing seaweed

4. developing binding agents

In order to investigate on developing a flexible and durable binder, I experimented with the following:

- Alginate (extracted from brown seaweed)

- Carrageen (extracted from red seaweed)

- Agar-agar (extracted from red seaweed)

- And more..

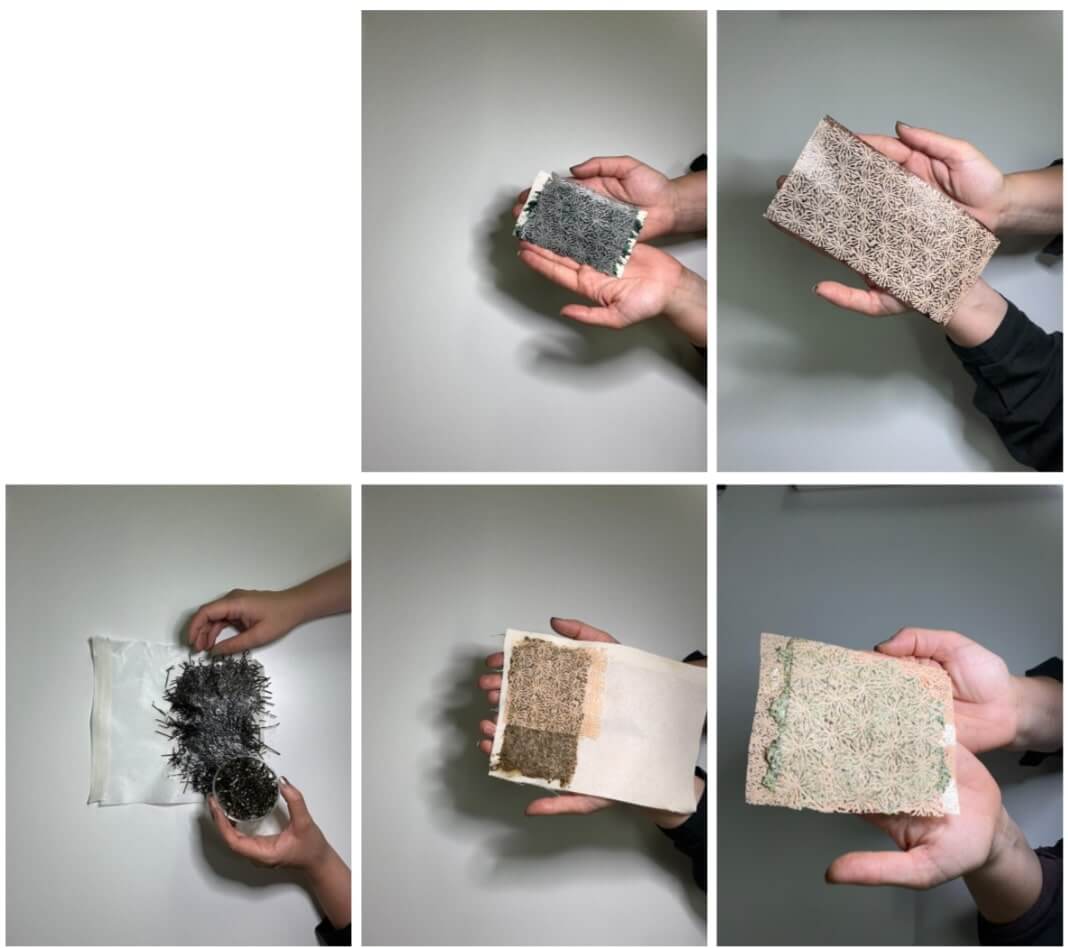

5. making plant-based material

After exploring diverse binder agents, laminations, topcoats combination with non-woven bonded textures, I further experimented with biodegradable algae PLA filament. The combined upper material made of PLA and under material made of TPU with the blend of algae pulp and binder agent worked out the most. The material’s texture is based on codium fragile seaweed for its natural appealing look.

b. creation of a sneaker using algae-based leather

1. sneaker pattern

Lasts and patterns for these particular type of sneakers (Nike Air Jordan 1).

The popularity of the sneaker world has grown immensely, affecting generations and all social layers of society.

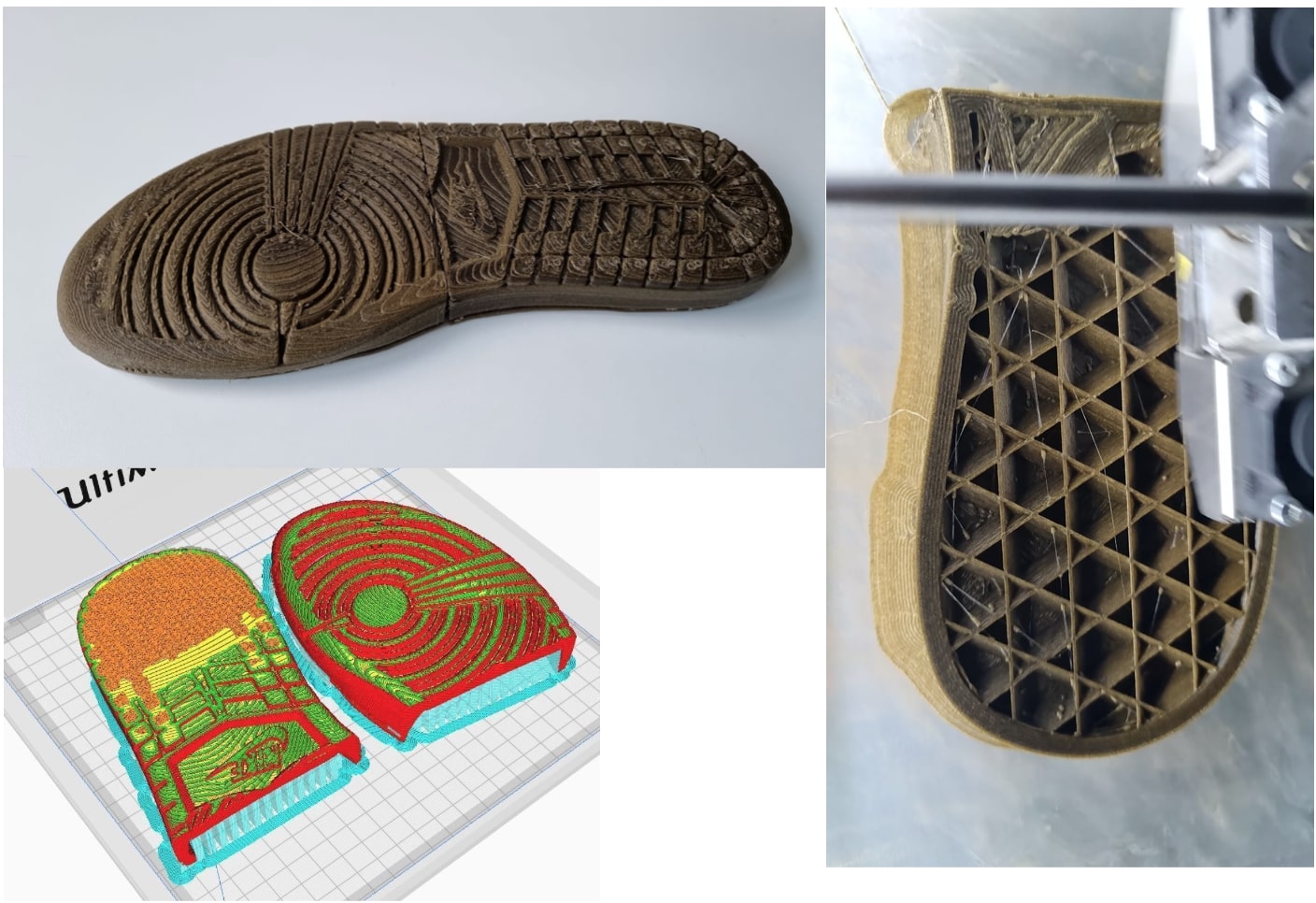

2. creating outsole

Based on a scanned actual sneaker sole I printed a 3D-biodegradable algae sole.

3. assembling sneaker

For the assembling the sneaker, I used thermoplastic glue.

4. final result

After movie

Credits

This research is made possible by support of:

Atelier Luma Arles | Wildwier | FILK | Sepatu Studios

Almere3D | Erasmus University Rotterdam | Fablab Amsterdam

Dorothy August | Minimuc Design Studio | illona.codes

AND to my mother Edita Chocholackova, John Caufijn,

Ruchama Hoed, Edouard Albert, Lauren Sanchez Calero and more.

Many thanks for the financial support of